Are you dealing with a refrigerant leak in your air conditioning system? Heard rumors about Freon R22 being illegal but unsure about what that means for you? Understanding what causes refrigerant leaks, how to spot them, and how to prevent further damage is essential for maintaining a well-functioning cooling system. This guide will walk you through everything you need to know about Freon leaks, from detection to repair, ensuring your system runs smoothly and efficiently.

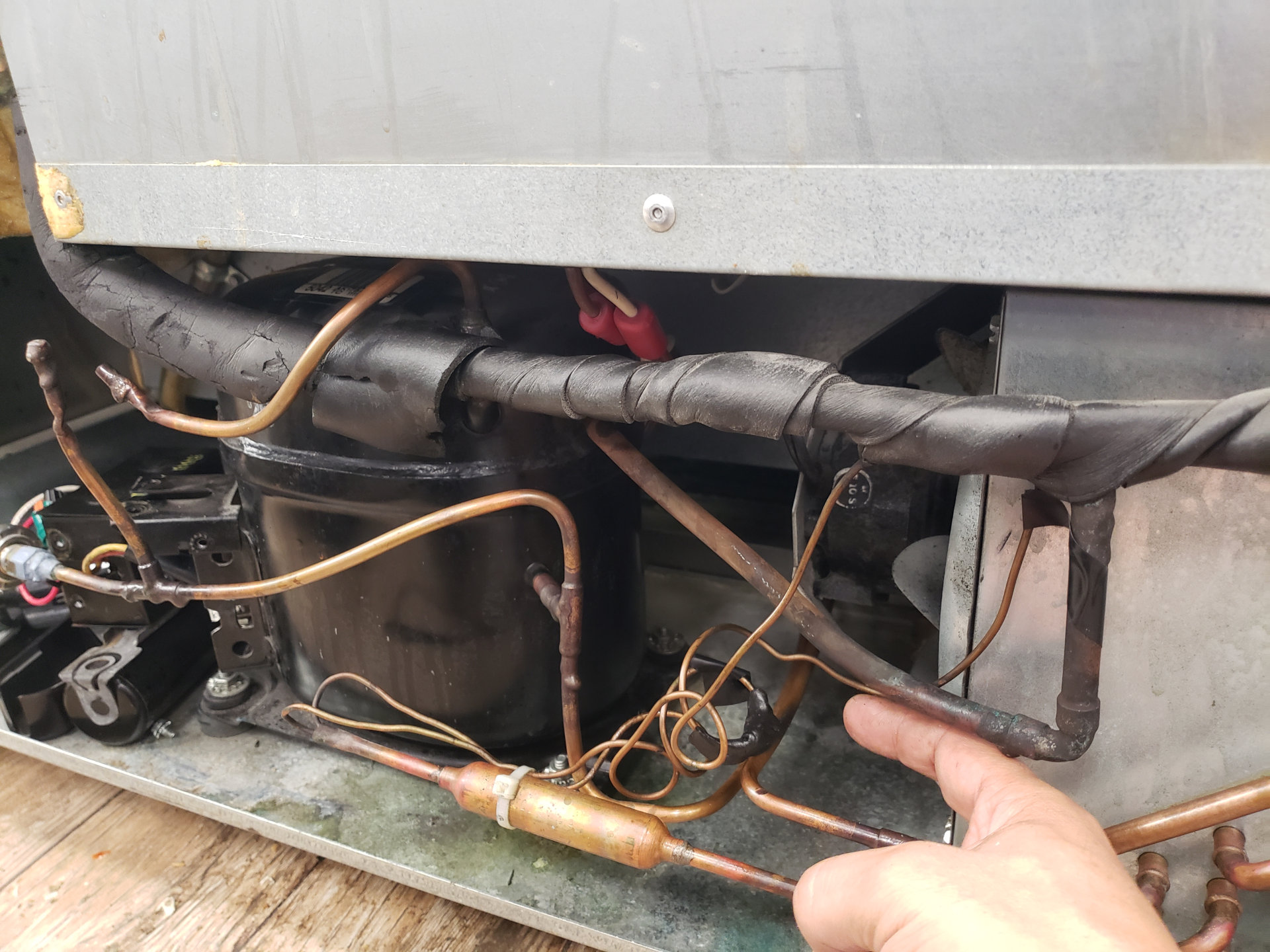

Sandwich Prep Table R404 Leak Detection and Repair at Bloomfield NJ

What Is Freon, and Why Does It Leak?

First, it’s important to clarify that "refrigerant" is the correct term for the chemical compound used in cooling systems to lower temperatures. Freon, often used colloquially, is actually a trademarked brand owned by Chemours and refers to specific types of refrigerants, including R12, R22, R410A, R502, and R503. These substances are commonly found in air conditioning systems and refrigerators, and they are typically non-flammable and low in toxicity.

However, these refrigerants—especially CFCs and HCFCs—are also environmental pollutants. This has led to global efforts to reduce their use and prevent the damage they cause to the ozone layer and the climate.

Why Refrigerant Leaks Are a Problem

Refrigerants, under normal conditions, are sealed within a system and don’t diminish over time. If your system is losing refrigerant, that means there’s a leak, and that leak can have serious consequences.

Here’s why addressing a refrigerant leak promptly is crucial:

- Reduced Cooling Efficiency: A refrigerant leak reduces the system’s charge, which lowers pressure in the evaporator. This can lead to frozen coils, obstructed airflow, and ultimately poor cooling performance. If your AC isn’t cooling as well as it used to, this could be the reason.

- Compressor Damage: Refrigerant carries lubrication oil throughout the system. A leak reduces the amount of oil, leading to higher internal temperatures and, eventually, compressor burnout—a costly repair.

- Overheating: When there isn’t enough refrigerant to cool the compressor, the compressor can overheat, causing it to fail. The compressor is the heart of your system, so overheating issues should not be ignored.

- Fire Hazards: While most refrigerants are non-flammable, some newer, more eco-friendly refrigerants, such as R290 (propane) and R600 (iso-butane), are flammable. Even a small spark could ignite these gases, creating a serious fire risk.

- Environmental Damage: Many refrigerants, like R12 and R410A, have high Ozone Depletion Potential (ODP) or Global Warming Potential (GWP). These chemicals contribute to global warming and ozone depletion, which is why many are being phased out by regulations like the Clean Air Act (CAA).

What Causes Freon Leaks?

Freon and other refrigerant leaks typically occur due to wear and tear on the system, improper installation, or corrosion. The most common causes include:

- Corroded Copper Tubing: Over time, refrigerant lines can corrode, especially if exposed to moisture or contaminants.

- Loose Joints or Connections: Vibration or improper installation can cause joints to become loose, allowing refrigerant to escape.

- Factory Defects: Occasionally, a new system may have defects in manufacturing that lead to early leaks.

- Age of the System: Older units are more prone to leaks simply due to the degradation of materials over time.

Sign of freon leak

Detecting a refrigerant leak can be tricky. Since refrigerant is colorless and odorless, leaks are often not obvious. Here are some signs that may indicate you have a leak:

- Poor Cooling: If your system isn’t cooling as effectively as before, despite being set at the right temperature, it could be a sign of low refrigerant levels.

- Ice on Evaporator Coils: If you see ice forming on the coils of your system, it’s likely that your refrigerant levels are too low, causing the evaporator to freeze.

- Hissing Sounds: These sounds often indicate that refrigerant is escaping from a small hole or crack in the system.

- Higher Energy Bills: A system with a refrigerant leak has to work harder to maintain the set temperature, leading to increased energy consumption and higher bills.

If you suspect a leak, it’s important to call in a certified technician who can locate and fix the issue using specialized tools. EPA 608 certification is required to handle refrigerants, and technicians without it could face heavy fines or penalties.

How Much Does It Cost to Fix Freon Leaks?

Repairing a Freon leak can cost anywhere from $500 to $1,500, and that price reflects the serious complexity of the job. While this may seem expensive, it’s important to understand that refrigerant leak detection and repair is a highly technical, labor-intensive process that requires trained, certified professionals—not something suited for DIY attempts.

Here’s why fixing a refrigerant leak is far more complicated than it might seem:

- Leak Detection: Locating a refrigerant leak is no simple task. Leaks can be tiny, hidden within hard-to-reach areas of the system, and often go unnoticed until they start causing performance issues. Technicians use advanced tools like electronic leak detectors and UV dye, which are essential for finding the exact source of the leak. Without the right equipment and expertise, leaks can easily be missed, causing further damage down the line.

- Confirming the Leak: Even after identifying a potential leak, professionals need to confirm it with precise methods like the soap bubble test. This step ensures the problem is pinpointed before any repairs can be made. Skipping or rushing this step can result in misdiagnosis or incomplete repairs.

- Refrigerant Recovery: This isn’t just about draining refrigerant. It’s a regulated process that requires specialized tools to safely remove the remaining refrigerant from the system without releasing harmful chemicals into the environment. Mishandling refrigerant recovery can lead to serious safety and legal issues, which is why only EPA-certified technicians should handle it.

- System Pressurization: After the refrigerant is recovered, the technician needs to pressurize the system with dry nitrogen to verify the leak. This stage requires precision and a deep understanding of the system’s pressure dynamics. If done improperly, it could lead to further damage or missed leaks, causing long-term issues.

- Leak Repair: Depending on the size and location of the leak, repairs can involve brazing delicate copper lines, sealing connections, or even replacing significant components like the compressor or evaporator coils. These repairs require advanced technical skills and experience. It’s not just about patching a hole; the entire repair process must be done with care, precision, and the right tools, otherwise, more harm than good can be done.

- Filter Drier Replacement: Whenever a system is opened, the filter drier must be replaced to prevent moisture and contaminants from getting into the system. This step is critical, as even a small amount of moisture can cause major damage to the system, leading to compressor failure or refrigerant contamination.

- Repressurization and Leak Test: Once the initial repair is done, the system is pressurized again with nitrogen, and a nitrogen pressure decay test is performed to ensure that no further leaks exist. This is a painstaking process that requires attention to detail and experience to get right. Any oversight can result in the system leaking again soon after the repair.

- Dehydration & Decontamination: To ensure the system is completely free of moisture and contaminants, a vacuum pump is used to evacuate the system. Moisture inside the system can freeze and damage internal components, so pulling a deep vacuum is a crucial step that takes both time and the right equipment.

- Deep Vacuum: The technician pulls a deep vacuum—down to 500 microns or lower—to ensure the system is fully evacuated. This step can take a considerable amount of time but is essential for ensuring the system operates efficiently once recharged. Even a small amount of moisture left behind can result in system failure.

- Recharging the System: Finally, the system is recharged with the exact amount of refrigerant it requires. This is not just about "topping off" the system—recharging involves carefully measuring and refilling the refrigerant to match the manufacturer’s specifications. Using too little or too much refrigerant can severely damage the system.

- Monitoring and Testing: Once the repairs and recharge are complete, the technician will carefully monitor the system’s performance. They check pressures, temperatures, and overall function to ensure the system is running smoothly and that there are no further leaks or issues. This final step is critical in preventing future breakdowns.

Why Freon Leak Repair Is Not a DIY Job

Repairing a Freon leak is an extremely intricate and technical process, requiring advanced tools, extensive knowledge of HVAC systems, and a solid understanding of refrigerant safety regulations. Attempting this as a DIY project could lead to serious system damage, void warranties, and potentially expose you to harmful chemicals. It’s also illegal for anyone who isn’t EPA-certified to handle refrigerants.

In short, this is a job for licensed professionals with the expertise to safely and effectively repair refrigerant systems. Attempting it without the proper skills and equipment can not only endanger the system but also your safety and the environment.

Preventing Future Refrigerant Leaks

The best way to avoid costly repairs is to prevent leaks from happening in the first place. Here are some tips:

- Regular Maintenance: Schedule annual check-ups with a certified technician to inspect the system and ensure it’s in good working condition.

- Keep the System Clean: Dirty coils and filters can lead to increased strain on the system, potentially causing leaks over time.

- Check for Corrosion: If you live in a humid or coastal area, keep an eye on any signs of corrosion on the unit’s outdoor components.

- Upgrade to a Newer System: If your AC unit is over 10-15 years old, it may be time to consider replacing it with a more efficient model that uses eco-friendly refrigerants.

Final Thoughts

Freon and refrigerant leaks aren’t just an inconvenience—they can lead to higher energy costs, damage to your AC system, and harm to the environment. Regular maintenance, early detection, and swift repairs are key to keeping your system running smoothly and extending its lifespan. If you suspect a refrigerant leak, don’t wait—reach out to an EPA 608-certified technician to resolve the issue quickly and safely.